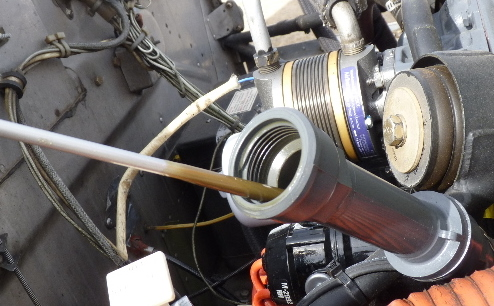

The oil system in an aircraft is integral to keeping the

engine running since it lubricates the engine’s many moving parts, removes

contaminants, prevents corrosion, cools the engine and cylinders, and creates a

seal between the pistons and cylinder walls (PHAK, 2016). To give a simple and

basic explanation of the oil system, it works by having the oil flow through

the strainer screen in the oil sump. The strainer screen filters out any

particles in the oil that could flow through the system and cause damage. The

oil then passes through a pump before going to either the oil cooler or oil

filter. If it is hot and needs to be cooled down, this is when it goes to the

oil cooler. On the other hand, if the oil is cool enough, it goes to the oil

filter where the lingering contaminates get filtered out that the strainer

screen did not get before. After this process, the oil goes to the engine to

cool, clean, and lubricate (Aircraft Systems, 2016). The oil system is monitored by the oil temperature gauge and the oil pressure gauge. The oil pressure gauge shows the pilot the pressure of the oil being supplied to the engine, while the oil temperature gauge shows the temperature of the oil.

One of the most important parts to this system is the oil

cooler. If it were to malfunction, the engine would no longer be cooled

internally by the oil. This could lead to engine damage such as the scoring of

the engine’s cylinder walls, warping the valves, and damage to the pistons and

rings, leading to a loss of engine power and detonation (PHAK, 2016). Another

issue with the loss of the oil cooler is that as oil heats up it becomes less

viscous, thus causing the bearings to have more friction. It is important that the

pilot monitors the temperature gauge to see if there is any excess oil heat and

to replace the oil cooler when necessary since it can become less efficient

over time due to carbon built up.

By monitoring the oil system gauges and doing the proper preventative and scheduled maintenance,

such as oil changes and cleaning of the strainer screen, the deterioration of

the oil system can be decreased and will be able to keep the engine’s performance

optimal.

(Word count: 411)

Aircraft Systems - 06 - Oil System. (2016, September

9). YouTube. Retrieved July 22, 2022, from

https://www.youtube.com/watch?v=cWDCXFwPLIs&list=PLzW-Ub1FWeZzdOHQhNK0U0Ci1a-VRH8IO&index=38

Federal Aviation Administration. (2016). Pilot’s Handbook

of Aeronautical Knowledge (PHAK). Retrieved July 22, 2022, from

https://www.faa.gov/regulations_policies/handbooks_manuals/aviation/phak/.

No comments:

Post a Comment